Butterfly

Learn About Butterfly Valves

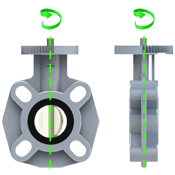

Butterfly valves control fluid by turning a disc to open or block the fluid flow path. The valve is mounted between pipe flanges, with the disc diameter matching the inside pipe diameter.

The most common type of butterfly valves are of "concentric" design: the turning axis and axial alignment of the disc are both centered with the valve body. Most concentric butterfly valves achieve sealing by compressing the edge of the disc against an elastomeric valve seat. This type of sealing is often referred to as "resilient seated" butterfly valves.

Other types of butterfly valves include double offset and triple offset. These designs can operate at higher pressures and temperatures than concentric designs and are sometimes referred to as high performance butterfly valves. For this discussion we will focus on concentric, resilient seated designs.

Butterfly valves use less material than comparably sized ball valves so they tend to cost less. They are also highly scalable. In fact, some hydro-electric dams have butterfly valves twelve feet in diameter. Ball valves of such size are often impractical.

However, flow volume is less because the disc remains in the fluid path, unlike ball valves which have a full port clearance. Also, since sealing is accomplished by radial compression of an elastomer, they operate at lower maximum temperatures and pressures than ball valves.

Nevertheless, the combination of lower cost and scalability make butterfly valves an excellent choice for many applications.

Butterfly valves consist of a valve body, valve seat, disc, stem, and stem packing.

The valve body for concentric, resilient-seated valves is typically made of cast or ductile iron. Cast iron costs less but is brittle and susceptible to rusting. All Valworx resilient-seated butterfly valve bodies are ductile iron.

The cast iron valve body is coated with a layer (or multiple layers) of protective paint. Other materials include PVC and stainless steel. The former is typically used in potable water applications and the latter for high performance valves.

EPDM is a commonly used elastomer for the valve seat. Other materials include NBR (Buna) and FPM (Viton). All of these can be used with water. Chemical compatibility with other media can be found here. Notably, Viton is well-suited for oil and gas applications.

The valve disc can be made out of a variety of materials, but higher quality valves use stainless steel for superior corrosion resistance. Valworx butterfly valves are made with 316 stainless steel discs.

The stem may be integral to the disc (ie a single piece) or made of two or even three pieces. What is important is the integrity of the connection. Most stem connections are welded.

Stem packing is usually made of the same material as the valve seat, and PTFE (Teflon) rings are often used for bearing surfaces because of their low friction properties.

Butterfly valves are also differentiated by the type of pipe connection. Wafer butterfly valves are mounted using bolts that pass through flange holes on the valve body. Lug butterfly valves are mounted via bolts that thread into threaded holes in the valve body. Lug-style valves are suitable for end-of-line use.

The flange holes are in pre-set patterns according to industry standards. Valworx butterfly valves conform to ANSI B16.5 Class 150 and 16.1 Class 125, among other standards.

They are cycled manually via a hand lever or, for larger valves, a gear operator.

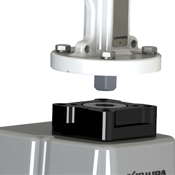

Butterfly valves can be easily actuated using brackets and couplers that attach to actuators. However, these linkages, and the attendant alignment problems that come with them, can be avoided altogether by using direct-mount butterfly valves. Direct-mount valves have mounting pads with holes drilled in a preset pattern such as ISO5211. The valve stem protrudes above the pad for easy insertion into the actuator output drive.

All Valworx butterfly valves are direct-mount, ready for actuation. Handles and gear operators are available for manual operation.

Given their scalability and lower cost, butterfly valves are often used in large pipelines for every type of media compatible with the materials of construction. Butterfly valves see widespread use in oil & gas, industrial, chemical and other industries.

Because they rely on compressing an elastomer for sealing, resilient-seated butterfly valves have lower maximum pressure and temperature limits.

In short, butterfly valves are an excellent choice where the required temperatures and pressures are moderate.