Stainless

Learn About Stainless Ball Valves

Stainless ball valves control fluid flow by turning a bored spherical ball to block or open the fluid path. They are available in 2- 3- or 4-way designs and, combined with a variety of available end connections, can be used in wide variety of applications.

Stainless ball valves offer significant advantages over other types of valves. For instance, stainless ball valves can open and close quickly unlike gate, globe and knife-edge valves which require multiple turns of a jack screw to completely cycle. Also, since the flow path is straight through the valve they have lower pressure losses and higher flow rates than comparably sized globe valves.

Similarly, unlike butterfly valves where the disc remains in the flow path, ball valve flow paths are unimpeded, enabling higher flow rates. However, because they use more material ball valves are not as scalable as butterfly valves and tend to cost more.

Stainless steel ball valves are available in two common alloys: 304 and 316. Of the two, 316 has a higher molybdenum content as well as nickel to maintain austenitic properties. The added metals combine in a way to create superior corrosion protection in 316, but since these metals are relatively expensive 316 costs more than 304. All Valworx stainless steel ball valves are made out of 316.Stainless steel ball valves' versatility and performance coupled with the corrosion resistance and the durability of stainless steel have made them the preferred choice for millions of installations worldwide.

Stainless steel ball valve components include a machined or soldered spherical ball to block or allow fluid flow, a valve body to house the ball, and stem packing and ball seats to seal the valve. A ball stem engages a slot in the ball which allows the ball to be turned by a handle or actuator.

There are various methods used to achieve sealing, but all ball valves have valve seats between the ball and the valve body, and stem seals (commonly called stem packing). PTFE (Teflon) and FPM (Viton) are common sealing materials.

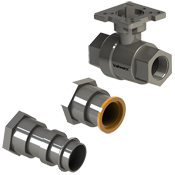

Stainless ball valves are connected to piping using threaded, flanged or welded-end connections. Threaded connections are the most common, as they allow easier removal of the valve. Of the different thread standards, National Pipe Thread (NPT) is the most common, and this is what we use for Valworx valves.

Another common connection is a flanged valve. Stainless flanged valves typically adhere to a standard design specification, ASME B16.5. Within this specification are different pressure classifications, such as Class 125, 150, 250, etc. This classification refers to the pressure rating at the boiling point of water, ie 212°F, or 100°C. At ambient conditions the rated pressure is higher. For a 150# flange, the rated pressure at ambient conditions is ~275psig.

A third connection method is tri-clamp, which uses a gasket and a clamp to connect to the piping. Because it does not have any threads or "dead spaces" where pathogens could grow, this type of connection is considered hygienic.

Stem packing varies by valve and material type, but it usually incorporates compressing a series of o-rings (or chevrons) to achieve a tight seal. The stem packing is kept compressed by Belleville washers (basically conical washers) acting as leaf springs. The washers compensate for micro-movements due to wear and temperature changes. This is commonly referred to as "live loaded" stem packing.

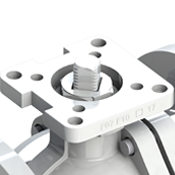

Stainless ball valves can be designed to be easily actuated. Actuators can be attached using brackets or by bolted to a valve mounting pad. Valves that do not require additional bracketry are sometimes referred to as "direct mount" valves.

Some manufacturers have their own specific mounting pad designs, but many, including Valworx, use a standard ISO5211 mount.

Ball valve application suitability depends on, among other factors, materials used for construction.

Stainless steel ball valves offer high corrosion resistance and high strength. Depending on construction they can be used for high pressure applications, in some cases over 3000psi. They are especially well-suited for cryogenic applications and are available with a variety of end connections.

Given their combination of strength, durability and corrosion resistance, stainless steel ball valves are the technology of choice for use in millions of applications worldwide.